Tel. (+82-43)533-9599 | E-mail. howsol@howsol.com

Tel. (+82-43)533-9599 | E-mail. howsol@howsol.com

Suitable for new constructions, as well as for renovation works. HOWSOLPAN is lightweight and rigid.

The continuous production process and unique bonding technology can guarantee lifelong the stubborn adhesion between aluminum coil to core material. And, it gives superior flatness.

Virtually all imaginable colors are available. Our roll coated color systems have perfect uniformity and when reproduced, no discrepancy has been observed comparing to the original.

As processing such as bending, folding and bending, routing, and rounding are extremely easy and it fits well to the precise and neat installation in accordance with designer's vision.

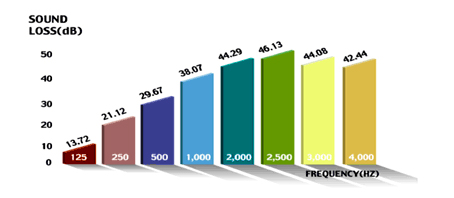

Noise reduction by the sound damping polymeric core material; thermal insulation effect through the low temperature conducting core material.

Thanks to antisoiling property of the suface coated PVDF, contaminants such as pollutant and dust can be easily removed from the façade by washing with minimum of normall synthetic detergent.

| ITEM | TESTING | RESULT | REMARK |

|---|---|---|---|

| Weight | - | 5.50 kg/㎡ | - |

| Density | - | 1.36 g/㎠ | - |

| Tensile Strength | KS B 0802 | 5.51 kg,f/㎟ | ASTM E 8 |

| Yield Strength | 5.1 kg/㎟ | ASTM E 8 | |

| Elongation | 8% | ASTM E 8 | |

| Flexural Elasticity | 4080 kg/㎟ | ASTM D 393 | |

| Thermal Conductivity (Average 20±5℃) |

KS L 9016 | 0.19 kcal/m.hr.℃ | ASTM D 976 |

| Deflection Temperature | KS F 2263 | 115℃ | ASTM D 648 |

| Linear Expansion | KS F 2263 | 24x10^6/℃ | ASTM D 696 |

| Bending Moment | KS F 2263 | 70kgf/cm | - |

| Bending Strength | KS F 2263 | 1.075kgf/㎠ | - |

| Peel Adhesive Strength | KS F 4737 | 25kgf/25mm | - |

| ITEM | TESTING | RESULT | REMARK |

|---|---|---|---|

| Gloss | 25 | ±5 | - |

| CCE | 11x11mm,6mm draw | Nopeel off | - |

| Pencil Hardness | 45 (Mitsubishi Unison) | H | KS D 0254 |

| ASTM D3363-74 | |||

| Flexibility | T-Bending | 1-T No Crack | ASTM D 4145-83 |

| Impact Test | 1000g x Φ12.7mm x 500 mmH | No peel off | - |

| Chemical | 5% Hcl, H2SO4 x 72 Hrs | Good | ASTM D-1308-87 |

| Resistance | 5% NaOH x 72 Hrs | Good | |

| Salt Water Spray | 5% Nacl x 5000 Hrs | Good | ASTM D-B117-90 |

| Adhesion : Dry Wet Boiling Water |

Method 8 37.8 ℃, 24 Hrs 100 ℃, 20 mm |

Good | ASTM D-3359 |

| Thickness | 2mm ~ 12mm |

| Width | 1,020mm, 1,250mm, 1,575mm |

| Length | less than 6,000mm |

| Surface Treatment | PVDF coating (25㎛ ± 5) |

| Color |

- Solid Color, Metallic Color and Stone Color - Please refer to our color chart and sample - Custom colors available with larger materials orders. |

[ Exterior ]

[ Exterior ] [ Interior ]

[ Interior ] [ Renobation ]

[ Renobation ] [ Signage ]

[ Signage ] [ Ceiling·Partition·Door ]

[ Ceiling·Partition·Door ] [ Furniture·Cloak Room·Packaging ]

[ Furniture·Cloak Room·Packaging ]